Our Hot Selling Equipment

Top Waste Tire Recycling Machine Manufacturer

In China With Customized Solution

We provide complete turn-key tire recycling solution from R&D, production until successfully installation at customer’s worksite. - designed to turn waste tyres into valuable products with maximum efficiency. From high-performance shredders to versatile and durable solutions, HVST offers a wide range of customization equipment to meet your tyre recycling needs and ensure profitability in your operations.

We Are Your Best Solution For Waste Tyre Recycling

Looking for a suitable tire recycling solution for your own tire recycling business? Search no further,rubber tyre recycling machine (or rubber /tire mulch machine) refers to a mechanical device specifically designed to shred or crush waste tires into small pieces.

HVST GROUP specializes in providing high quality standard or customized waste tire recycling line with different capactiy and final applications, including but not limited to TDF lines, rubber mulch line, rubber crumb line, rubber powder line.

(TDF)Rubber Shredder Machine Line

rubber tyre mulch recycling machine

rubber tyre recycling machine

rubber tyre recycling machine

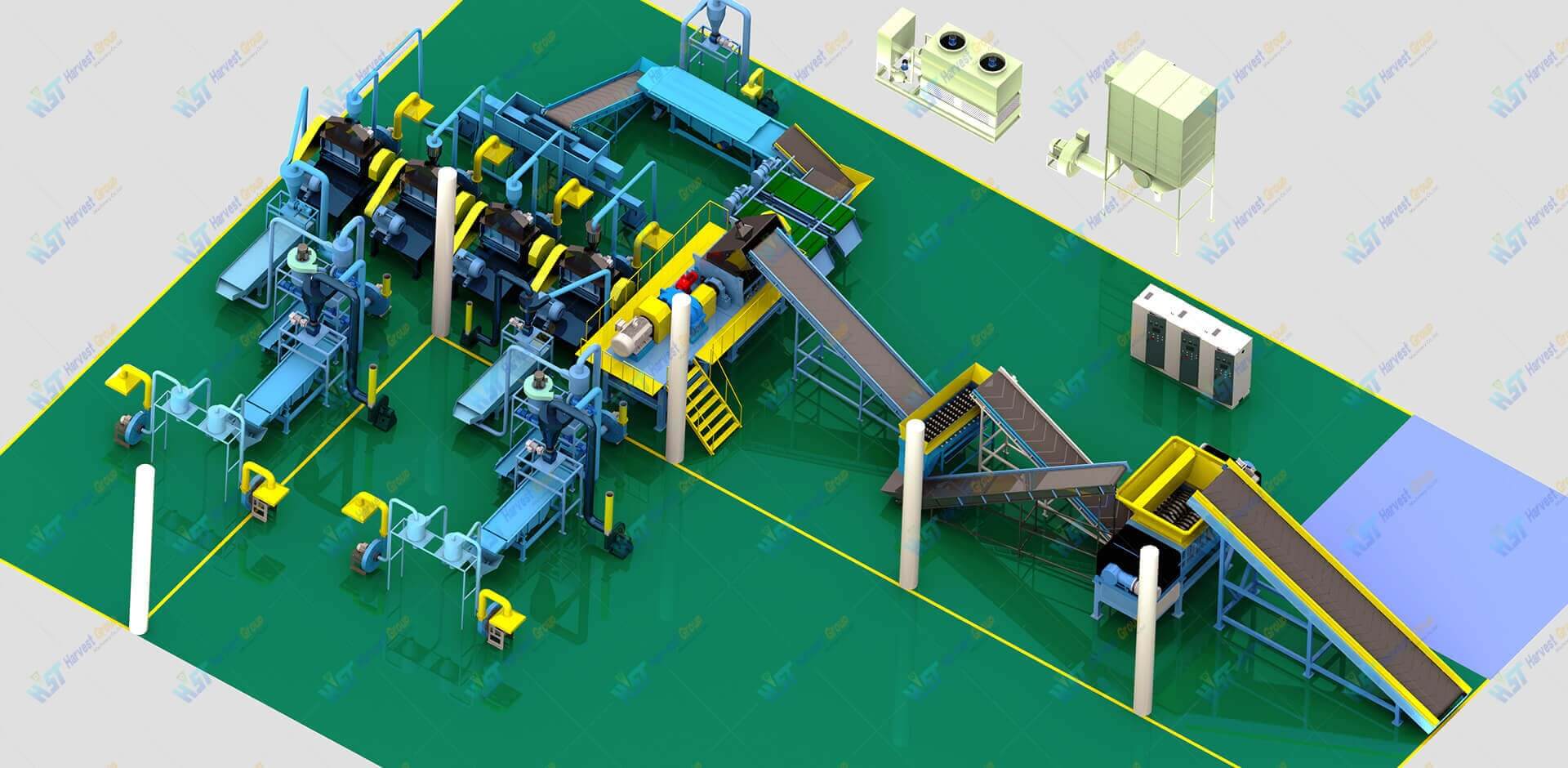

Flow chart of semi automatic xkp tire recycling line

Whole tire--tire circle cutter--tire strip cutter--tire slice cutter--rubber crusher--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

Whole tire--tire circle cutter--tire strip cutter--tire slice cutter--rubber crusher--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

Fully automatic xkp rubber recycling plant machine

Tire Cutting Machine(Tire debeader)--(Tire cutter)--Rubber Shredder Machine --Rubber crusher--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

Tire Cutting Machine(Tire debeader)--(Tire cutter)--Rubber Shredder Machine --Rubber crusher--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

waste tyre recycling plant

waste tire recycling machine

waste tyre crusher machine

scrap tyre recycling plant

Waste Tire Recycling Production Line & waste Tyre Recycling Equipment

Waste tire—Wire drawing machine—Rubber shredder— Steel wire separating machine—magnetic separating —Rubber powder.

1.Steel wire drawing machine–extract the thick steel wire.

2.Conveyor-Transport the tire to the shredder. Double-shaft shredder–shred the tire into 5-10mm.

3.Recirculation system–To control the size of shreds going to the rasper; Raspers-Reduce the shreds into 15~20mm chips and liberates steel from the rubber;

4.Over belt magnet–Separation of liberated steel from the rubber chips; Vibratory feeder–Transports the rubber chips;

5.Rubber granulator machine–Size reduction of the chips to 1-6mm granules and liberates the textile fraction to air flow separation.

6.Grinder machine –Grinder rubber powder.

7.Dust Collector–Remove dust and fines from the system and filter the air before returning it to the atmosphere.

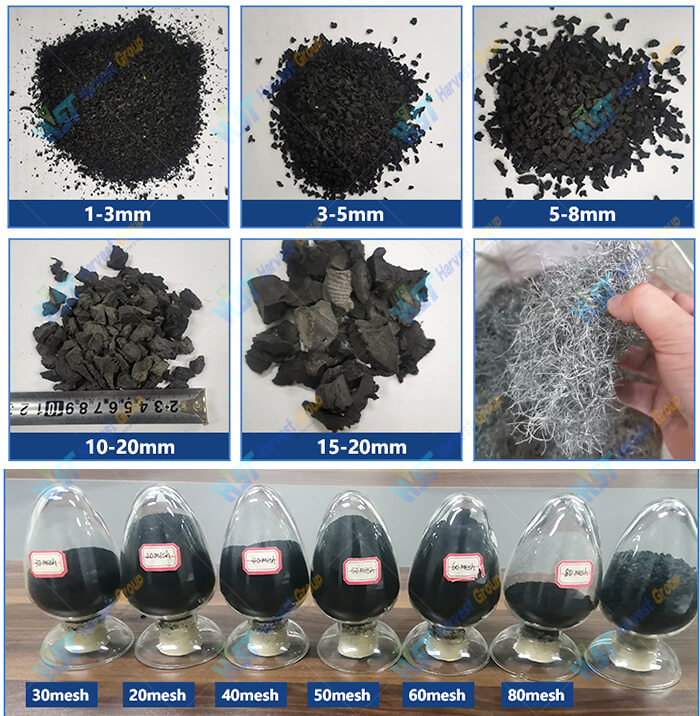

Tire Shredding System / TDF & TDA Production

Raw Material: car tires, truck tires and OTR tires

Output Material: 50~150 mm tire chips

Main Machines: tire shredder

Capacity: 1000~30,000 kg/h

Wire Steel Separation System.

Main Machines: tire shredder(Tire Recycling Shredder), tire rasper

Output Material: 10-30mm rubber mulch, wire steel

Capacity: 500~15,000 kg/h

Rubber Granulation and Fiber Removal System

Main Machines: tyre shredder,tyre rasper, tyre granulator machine

Output Material: 1-5mm rubber crumbs, nylon fiber, steel

Capacity: 500~10,000 kg/h

Rubber Powder Grinding System

Main Machines: tire shredder, rasper, granulator, fine miller

Output Material: 20~100 mesh powder

Capacity: 100~10,000 kg/h

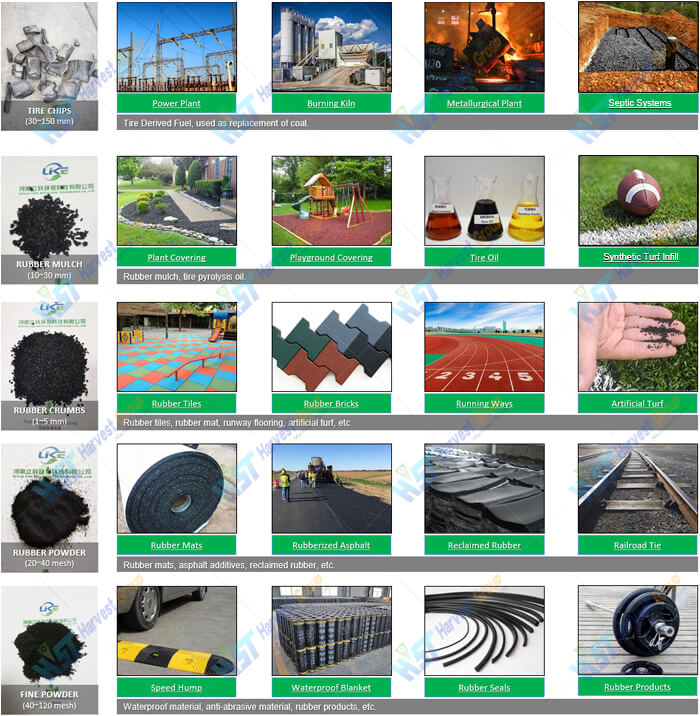

Tyre Recycling and Shredding Products

Reliable tyre recycling equipment is designed to turn waste tyres into valuable products, such as rubber granules, rubber powder, tyre - derived fuel (TDF), steel wire, and fiber materials. Reliable offers a variety of customizable recycling production lines to meet your different requirements. Welcome to consult!

Get ready to succeed with Reliable in tyre recycling. Don't compromise on your equipment

Choose waste tire recycling machines that industry leaders trust. Click here for a seamless investment in technology that works as hard as you do. Make the switch today and feel the difference!

Customized Service

Customized Service

Provide customized production line services based on customers' raw materials, capacity and costs, etc.

Quality Assurance

Quality Assurance

Our company has passed ISO9001 quality system certification and CE certification.2 Year Warranty

Installation and Training

Installation and Training

We could dispatch our experienced engineers to your site for technical support, or online video installation, operation, and maintenance instructions support.

Competitive Price

Competitive Price

We provide quality and reliable original spare parts at the most reasonable and favorable price.

We are trusted by more than 1,000 clients

Are you ready to be next? Click here and work with us where excellence is not just promised—it’s delivered

We have 20 years experience in manufacturing waste tire recycling machine,Transform Waste Tire into Worth With HARVEST! Get waste tire recycling systems designed to save you costs and maximize efficiency. Our professional team is standing by to offer you comprehensive services from design to training.Get a Free Quote Now!