Feed size: 1-4/h,Customized. Productive Capacity 1-15/h,Customized.wood.

This series of wood pellet burners can be widely used in heat exchange equipment such as hot air furnaces, heat exchangers, aluminum melting furnaces, aluminum rod heating furnaces, etc. and has the following characteristics: The ring die pellet machine and the burner are easy and safe to operate, easy to clean andmain -tain, compact in structure, and space-saving. The pure sawdust biomass pellet burner is energy -saving and is an ideal heating equipment for plants.

(1) High pellet forming rate: The static mold and rotating pressure wheel design avoids secondary crushing of pellets, and the forming rate can reach about 99%, and the pellets are of uniform length.

(2) Balance between output and quality: Some models have double-layer molds that can be used in both directions, reducing costs and increasing output; the pellets produced have high hardness, smooth surface, and internal maturation, such as feed pellets, which can improve nutrient digestion and absorption and kill pathogenic microorganisms.

(3) Efficient power system: The biomass pellet machine adopts an efficient power system and intelligent control technology, which can reduce energy consumption and reduce machine wear while ensuring output power.

(4) Renewable raw materials: It can be applied to the processing of a variety of raw materials, including wood, straw, plants, waste wood and industrial pellets. Through processing, resources can be reused and environmental pollution can be reduced.

We have different metal crusher systems to Meet different market needs. Type1:

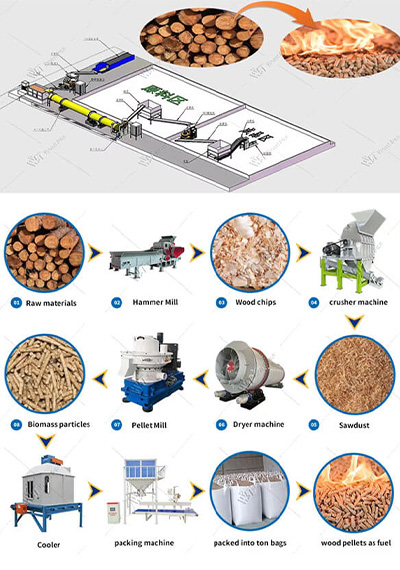

1. Wood crusher

2. Central dust removal system

3. Hot air furnace

4. Dryer

5. Pellet machine

6. Conveyor

7. Cooler

8. Packaging machine

|

Model |

Power(kw) |

Pellet size (mm) |

Inner dia(mm) |

Capacity(t/h) |

Dimension (mm) |

Weight (t) |

|

HM-450 |

55 |

4-12mm |

450 |

0.3-1 |

2200*900*1600 |

3 |

|

HM-550 |

75 |

4-12mm |

550 |

0.7-1 |

2300*1000*1780 |

5 |

|

HM-560 |

90 |

4-12mm |

560 |

1-1.5 |

2600*1300*2300 |

6.3 |

|

HM-580 |

110 |

4-12mm |

580 |

2-2.5 |

3200*1400*2400 |

8.5 |

|

HM-850 |

220 |

4-12mm |

850 |

2-3 |

3750*1650*3250 |

12.6 |

|

HM-880 |

315 |

4-12mm |

850 |

3-4 |

4300*1900*3600 |

14.5 |