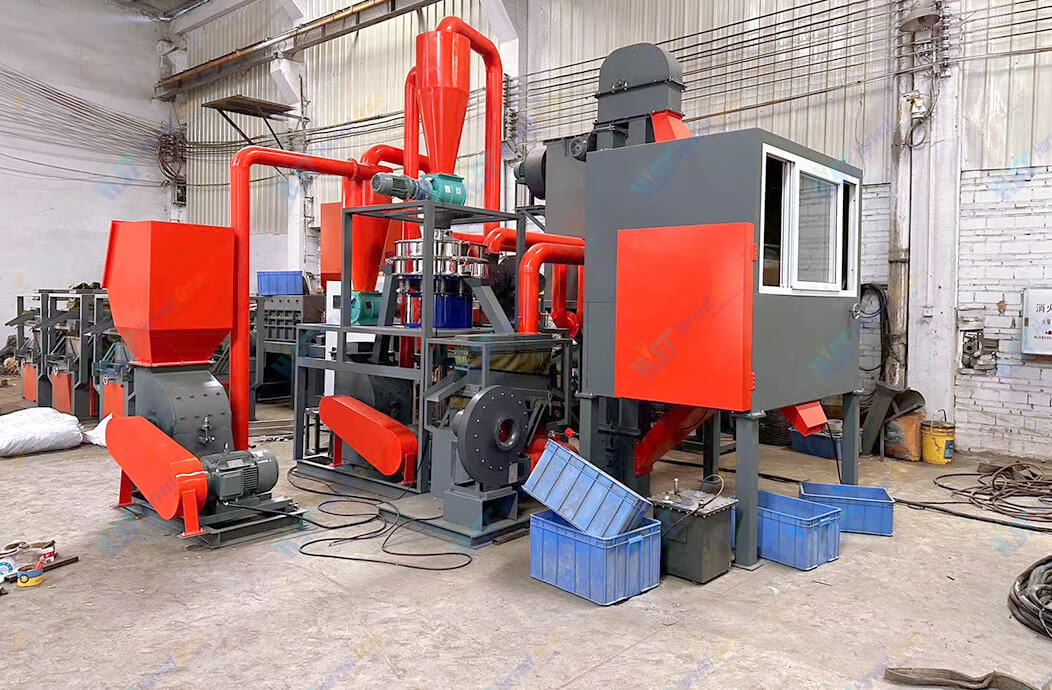

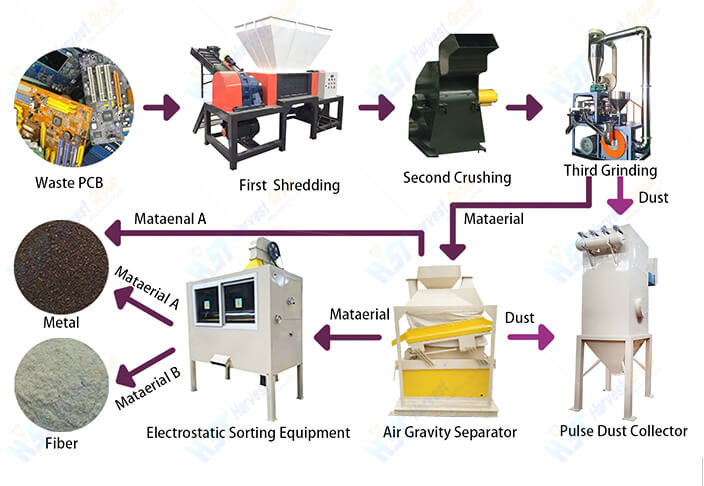

HVST is specialized in providing Complete E Waste Recycling Plant:

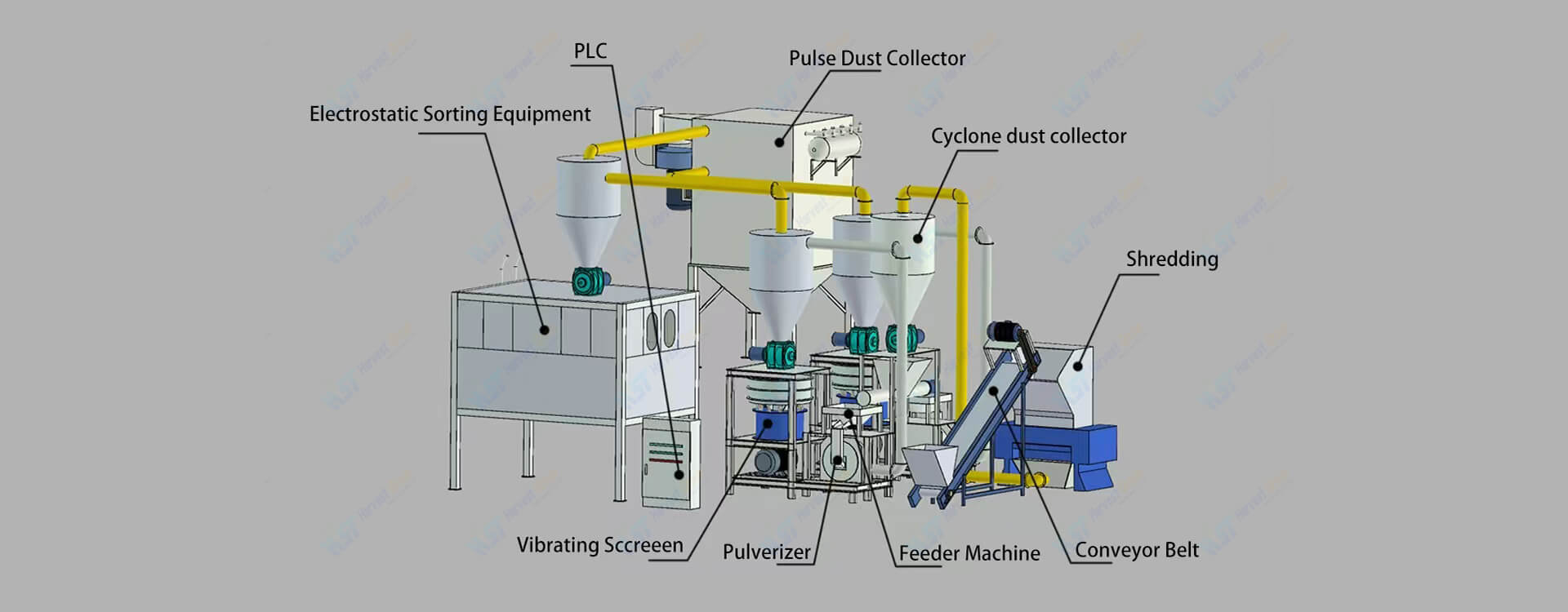

1. PCB Dismantling 2. Crushing and grinding 3. Air Separation 4. Magnetic Separation 5. Electrostatic Separation 6. Refining

PCB recycling machine is used for recycling all kinds of waste printed circuit boards, like computer boards, TV panels, aluminum-plastic panels, and copper plates; processing waste electrical appliances, like used TV sets, waste refrigerators, waste computers, waste air conditioners, and other waste materials

Professional E-Waste Recycling Plant Manufacturer – HVST

As a leading manufacturer of E-Waste Recycling Plants, we provide highly efficient and reliable machinery

for extracting precious metals like gold, silver, copper, and palladium from electronic waste.

Our advanced solutions not only reduce environmental pollution but also maximize resource recovery, turning e-waste into lucurable profits.

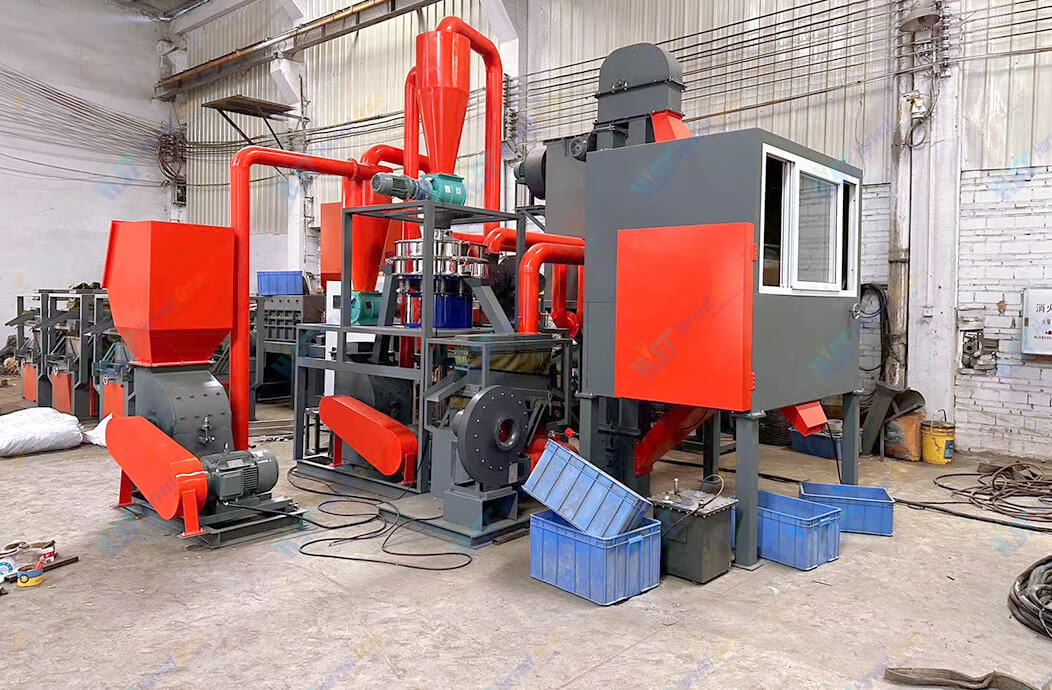

Our PCB recycling system integrates shredding, milling, sorting, and dust collection, with full PLC automation control. The process includes: shredding → grinding → vibration screening → gravity separation → electrostatic separation → pulse dust collection. Incompletely separated materials are reground for maximum efficiency, achieving 99% metal/non-metal separation. The output includes high-purity metal/non-metal concentrates, while dismantled valuable components are further refined for resource recovery.

The final products of Waste circuit board electronic component dismantling machine is electronic components include Tin slags, IC chips, Capacitors, CPU/RAM etc.

Capacity : 150-250kg/hr

Key Features:1. The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3. The crushing part uses shredding, smashing and crushing processes, and circulating water cooling is used inside and outside the crushing chamber.

4. Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

5. The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.

We provide both standard and customized e-waste recycling systems to match your operational demands

Our standard solutions handle 150–5,000 kg per hour, serving as a flexible foundation for specialized requirements—whether refining specific metal fractions or integrating cable and e-waste processing. Let us design the ideal solution for you.

Our PCB recycling machine efficiently processes various printed circuit boards (PCBs), including computer, mobile phone, and TV boards, as well as copper-clad laminates and other e-waste. It separates mixed metals (copper, gold, silver, etc.) from non-metallic materials (fiber, resin), ensuring high-purity recovery.

With a separation efficiency of up to 99%, this system transforms waste into valuable resources while delivering significant economic and environmental benefits.

|

Model |

Power (Kw) |

Recovery percent (%) |

Collection coefficient(%) |

Output(kg/h) |

Size (mm) |

Weight (kg) |

|

PCB-1000 |

45 |

≥99% |

≥99% |

150-200 |

6000*7500*4200 |

4250 |

|

PCB-1500 |

68 |

200-300 |

7000*8200*4500 |

6500 |

||

|

PCB-1800 |

110 |

300-500 |

8000*11000*4800 |

8500 |

||

|

PCB-2000 |

198 |

1000-1200 |

8200*16000*5250 |

12500 |

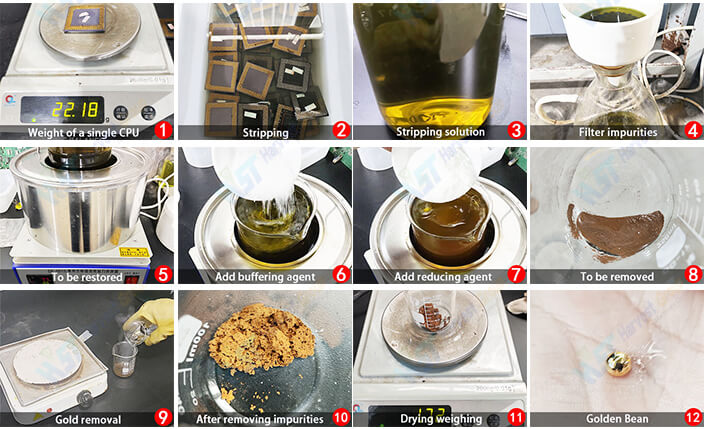

1. Weighing a single CUP 2. Deplating

3. Extracting deplating solution

4. Filtering impurities

5. Waiting for reduction 6. Adding buffer

7. Removing impurities from gold

8. Drying and weighing

9. Obtaining gold beans

1.Component Removal

Extract gold/silver parts (chips, ICs) from PCBs. Soak pins in acid for de-pinning.

2.Copper-Silver Separation

Mix carbonized powder with reagent solution in reactor. Heat and stir.

3.Silver Recovery

Chemically reduce silver to metallic form.

4.Gold Leaching

Add leaching solution to reactor with residues. Heat for 3.5 hrs, then filter.

5.Gold Extraction

Use solvent extraction to concentrate gold, then precipitate via reduction.

6.Refining

Smelt to obtain pure gold & silver.

1.Cleaning & Gold Stripping

Thoroughly clean the gold-plated materials, then immerse them in the gold stripping solution until complete deplating is achieved. Reuse the stripping solution until no more gold can be removed.

2.Precipitation of Gold

After stripping, filter the solution and heat it in a furnace. While stirring, add a buffer agent, followed by a gold precipitant and a rapid settling agent. Stir for 3-5 minutes, then allow it to settle—the black or yellow sediment is gold mud.

3.Purification & Smelting

Let the solution settle for one hour, then filter out the liquid. Boil the gold powder in clean water, cool, and decant. Repeat this process twice. For higher purity, treat the gold powder with an acid solution, boil, cool, and decant. Rinse 2-3 times with clean water. Finally, filter, dry, and smelt to obtain ~99% pure gold.

|

Model

|

Capacity

|

External dimensions

|

Electrolyte volume

|

Output

|

Recycle rate

|

Purity |

|

HVST-5

|

5kg/d

|

1800*900*1900mm

|

12L

|

1.8kg

|

≥99%

|

≥99% |

|

HVST-10

|

10kg/d

|

1800*900*1900mm

|

24L

|

3.6kg

|

||

|

HVST-20

|

20kg/d

|

2200*950*1900mm

|

48L

|

7.2kg

|

||

|

HVST-30

|

30kg/d

|

2200*950*1900mm

|

56L

|

8.4kg

|

||

|

HVST-50

|

50kg/d

|

2200*950*1900mm

|

96L

|

14.4kg

|

Note:

1.The equipment shown is our standard model, but actual configuration varies depending on your specific materials. Please consult us for details.

2.Machine voltage can be customized to meet your local requirements.