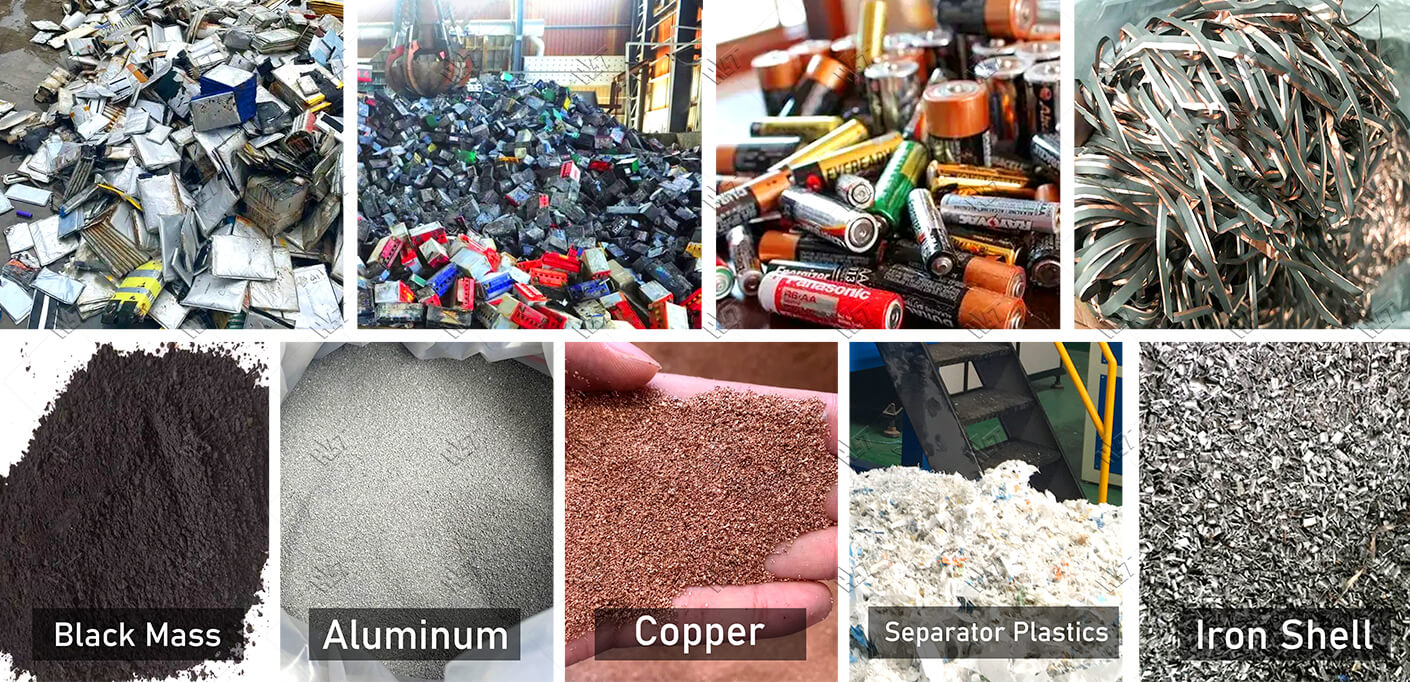

The technical solution of this equipment is mainly aimed at lithium batteries for scrap treatment.

Based on the material characteristics of lithium batteries, combined with advanced technology at home and abroad, the positive and negative electrode materials and valuable metals are separated mainly by physical crushing methods, shredding, high-speed crushing, roller screening, and screen screening processes.

Finally, positive and negative electrode materials, copper, aluminum, and other materials are obtained.

Processing materials: large aluminum shell lithium battery, soft pack lithium battery, steel shell lithium battery, positive electrode plate, etc.

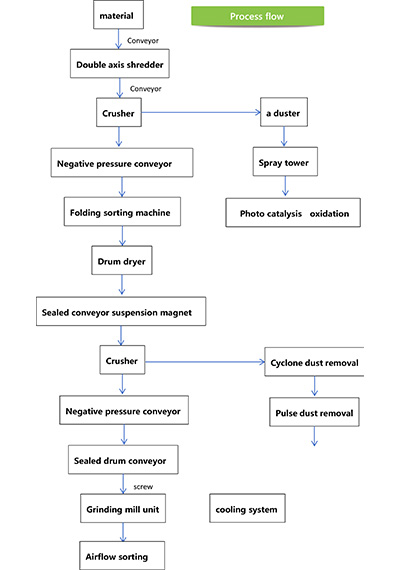

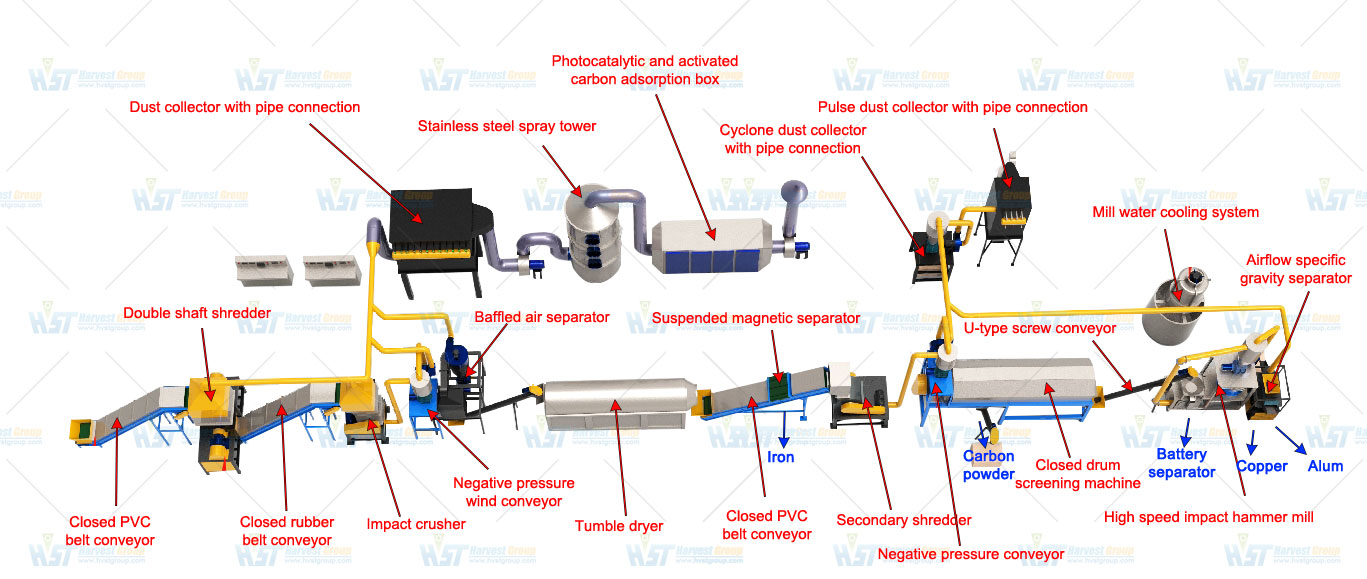

First, scrap lithium battery equipment process introduction:

(1)Pre-treatment: The waste lithium battery is discharged through a continuous needle discharge device to release energy in the battery.

(2)Primary treatment: The lithium battery enters the shredder through the automatic conveying system for preliminary crushing.

(3)Deep crushing: Through the multi-stage crushing system, the shredded material is processed twice to reach 20 mesh particle size.

(4)Air separation: The induced draft fan works with the cyclone feeder to separate the diaphragm paper from the positive and negative electrode pieces.

(5)Magnetic separation: Equipped with magnetic separation equipment to effectively separate iron materials.

(6)Vibrating screen: Through the high frequency linear vibrating screen, according to the size of the material. Divided into black powder, metal and other.

(7)Specific gravity separation: Copper and aluminum are separated from metals with a separation efficiency of up to 98%

(8)Dust treatment: The use of negative pressure system and pulse dust collector to recover the black powder in the exhaust, while ensuring that the exhaust air is dust-free

(9)Tail gas treatment: the tail gas is treated by special equipment to remove fluoride, phosphorus, etc., to meet the national environmental protection emission standards.

The lithium battery recycling plant is used for dismantling and recycling the Soft package battery, cellphone battery,Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration. The final products of this plant is Graphite powder, Cobalt acid lithium,Aluminum and copper.

|

Model |

Dimensions (length * width * height mm) |

Power (Kw) |

Capacity (kg/h) |

usable area |

|

DC-500 |

4000mm*1100mm*800mm |

361KW |

500kg/h |

600m2 |

|

DC-1000 |

5000mm*1200mm*800mm |

442KW |

1000kg/h |

650m2 |

|

DC-1500 |

7000mm*1000mm*600mm |

660KW |

1500kg/h |

700m2 |