Capacity: 80-1200kg/h Pellet size:2/6/8/10/12mm, Customized. wood.

The main process is to drive the main shaft through the motor to rotate the pressing wheel. The material is transported between the flat die and the pressing wheel. Under the extrusion of the pressing wheel, the material is squeezed out from the die hole of the flat die to form particles. Its working principle is: after the material enters the granulation chamber, the mold rotates and the friction pressure wheel rotates, so that the material is squeezed into the mold hole and compacted into a cylindrical strip. Then, it is cut by the cutter at the discharge port to form the required particles.

(1) Simple structure: The flat die pellet machine is mainly composed of a flat die, a pressure roller, a transmission device, etc. The structure is relatively simple and there is no complex internal structure. This makes the equipment easier to manufacture and assemble, the cost is relatively low, and it is also easy for operators to understand and master the working principle and operation method of the equipment.

(2) Strong adaptability: The flat die pellet machine has strong adaptability to materials, especially suitable for processing materials with high fiber content and relatively low hardness. It can process and shape materials with different humidity and particle size well. Even if the humidity of the material is slightly high, qualified pellets can be produced by properly adjusting the process parameters.

(3) Convenient for integrated production: Due to the small footprint, it can be integrated with other related equipment for design and layout to form a compact biomass pellet production system. For example, the pellet machine can be integrated with raw material storage equipment, crushing equipment, drying equipment, etc. to form an efficient production line to improve production efficiency.

We have different metal crusher systems to

Meet different market needs.

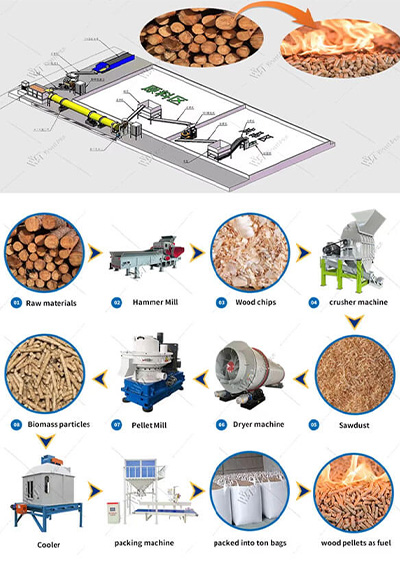

Type1:

1.Wood crusher

2.Central dust removal system

3.Hot air furnace

4. Dryer

5. Pellet machine

6.Conveyor

7.Cooler

8.Packaging machine

|

Model |

Power(kw) |

Pellet size (mm) |

Inner dia(mm) |

Capacity(t/h) |

Dimension (mm) |

Weight (t) |

|

PM-450 |

55 |

4-12mm |

450 |

0.3-1 |

2200*900*1600 |

3 |

|

PM-550 |

75 |

4-12mm |

550 |

0.7-1 |

2300*1000*1780 |

5 |

|

PM-560 |

90 |

4-12mm |

560 |

1-1.5 |

2600*1300*2300 |

6.3 |

|

PM-580 |

110 |

4-12mm |

580 |

2-2.5 |

3200*1400*2400 |

8.5 |

|

PM-850 |

220 |

4-12mm |

850 |

2-3 |

3750*1650*3250 |

12.6 |

|

PM-880 |

315 |

4-12mm |

850 |

3-4 |

4300*1900*3600 |

14.5 |