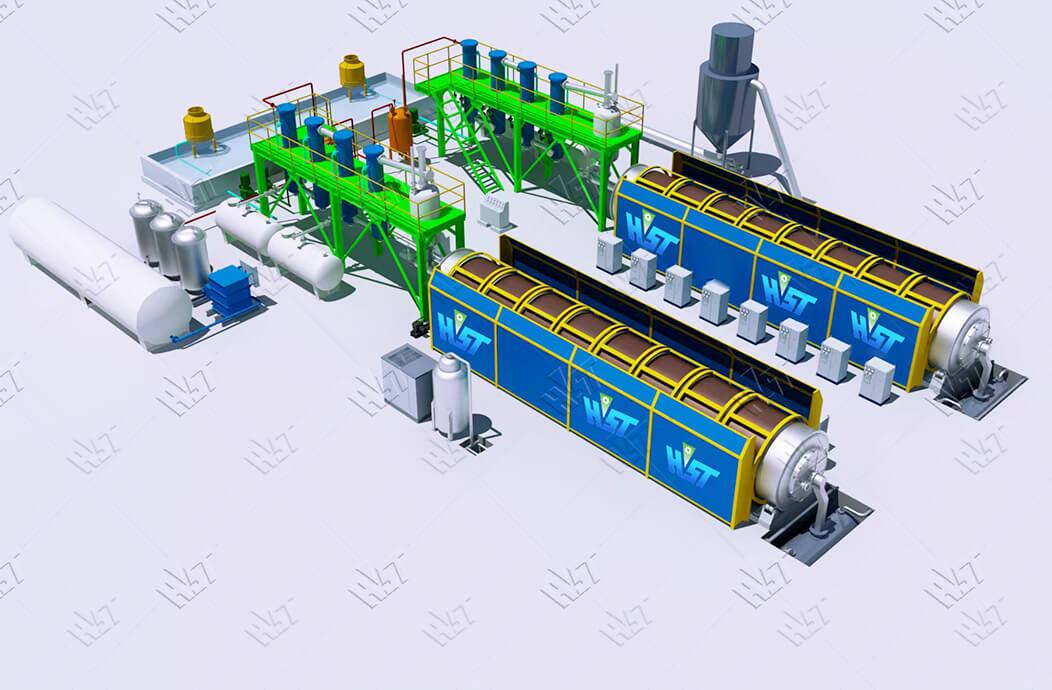

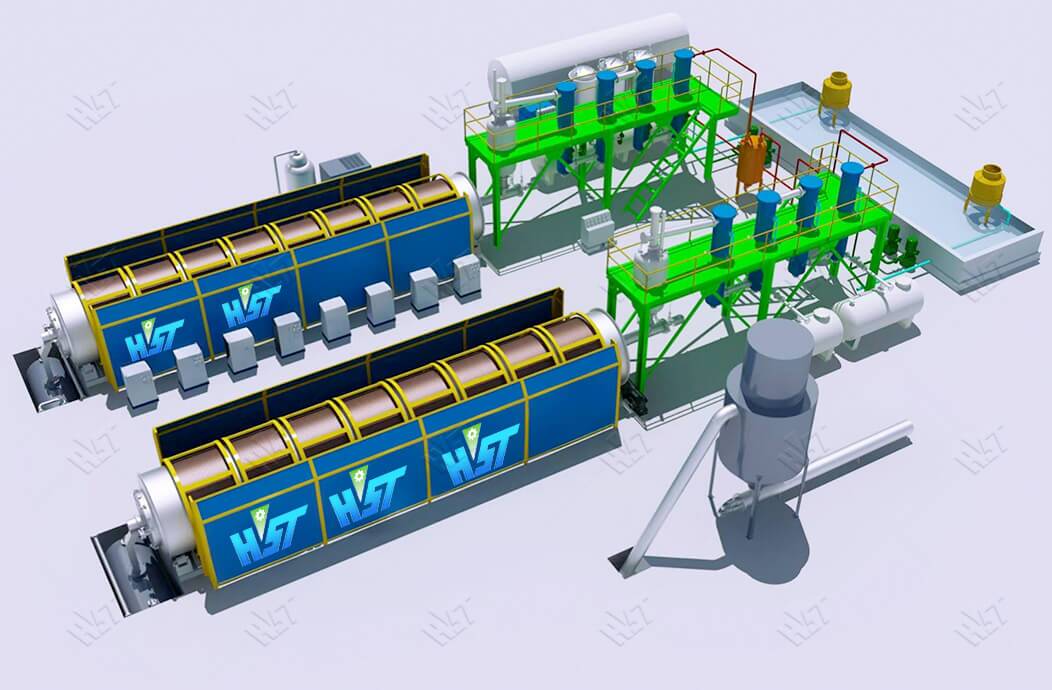

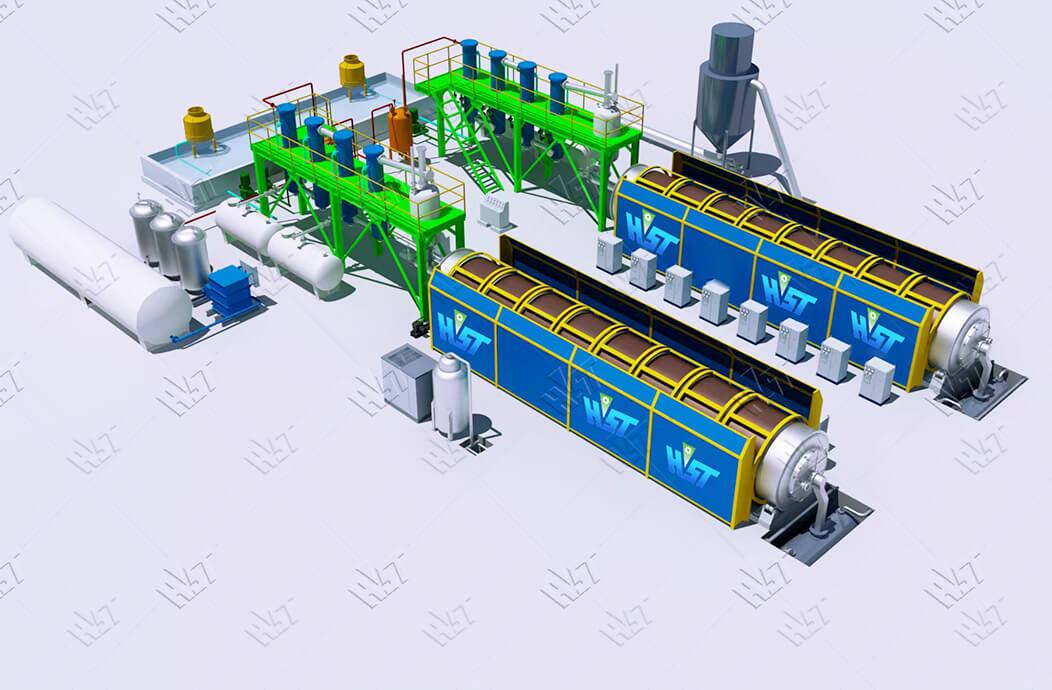

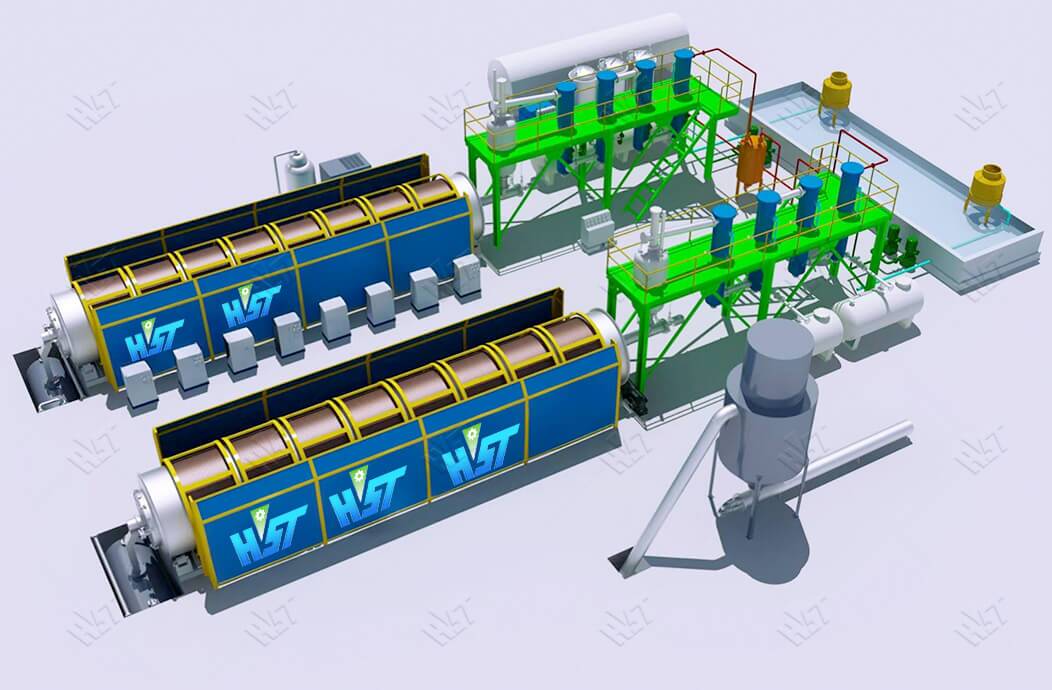

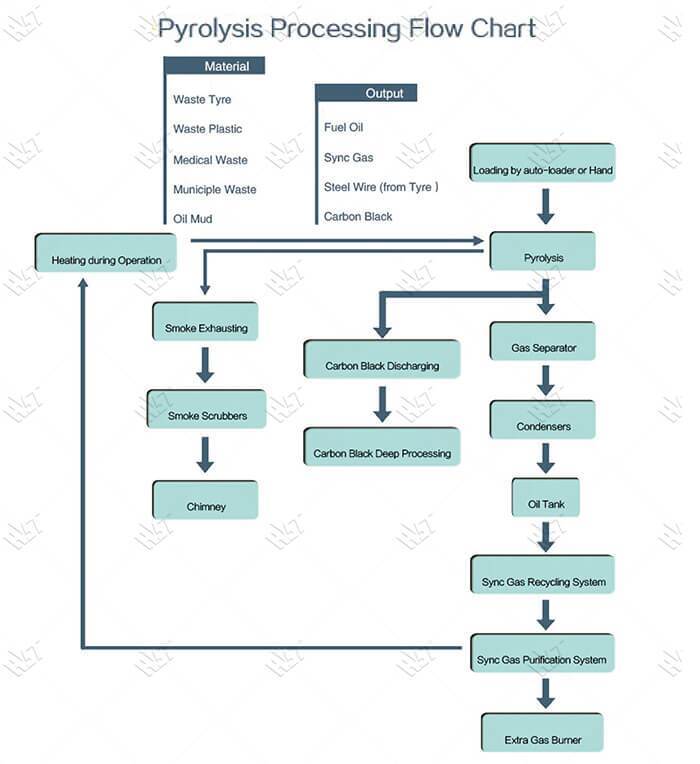

Pyrolysis technology offers a practical solution to recycling of waste tires, plastic, woods, domestic garbage, oil sludge, biomass oil . The original raw materials to make tires which are:

Rubber (natural and synthetic) 41%

Fillers (carbon black, silica, carbon, chalk…) 30%

Reinforcing materials (steel, polyester, rayon, nylon) 15%

Plasticizers (oils and resins) 6%

Chemicals for vulcanization (sulphur, zinc oxide…) 6%

Anti-ageing agents and other chemicals 2%

Are 100% recycled and become usable products with marketing values. Tire pyrolysis plant not only solves the environmental problem of used tires, but also create a profitable business with high ROI.

Safety :

1. Automatic welding, improve work efficiency, ensure quality of waste tyre pyrolysis plant, avoid accidents.

2. Special design to avoid paper jam caused by X-ray inspection and ensure safe operation.

3. The vacuum system ensures that the entire production line runs well.

Environmental protection :

1. Dust removal and sulfur removal system to remove smoke and sulfur.

2. Exhaust gas (including methane to butane) will be directly recycled to the fuel furnace without gas pollution.

High oil yield:

1. Three cooling processes ensure that the oil and gas are fully liquefied.

2. The catalyst chamber ensures complete pyrolysis of the feedstock.

Long lasting:

1. Special boiler plate: Q245R,stainless steel,15Crmo, with a thickness of 18mm.

2. Automatic welding ensures the service life of the waste tyre pyrolysis plant and the service life will reach 8-10 years.

Energy saving:

1. The heating system of waste tyre to fuel oil pyrolysis plant is well-sealed, airtight, and fuel-efficient.

2. Exhaust gas will be recycled for reactor heating.

Good after-sales service:

1. Overseas tour guides install and train customer staff and try to run.

2.One year warranty.

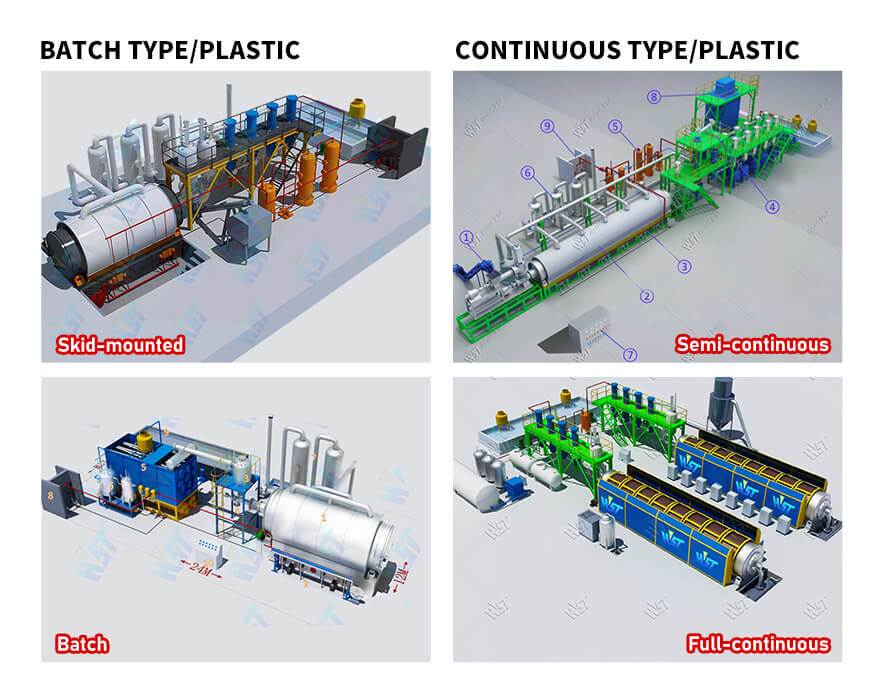

1.Automatic feeding:Speedy loading in and slag removal; Easily cooling down after one batch finished,saving time;No leaking with special high temperature flexible Graphite packing;

2.High condensing efficiency condensers with more oil output.Good quality oil,longer lifetime,and easy to clean;

3.National Patent Water Fim Smoke Scrubbers:Efficient removal of the acid gas and dust of the smoke,environmental friendly to meet related national standards;

4.National Patent Carbon Black Discharging System:Speedy fully enclosed Auto-discharging under high temperature,avoiding carbon black pollution,saving time;

5.Automatic submerged welding technology,ultrasonic nondestructive testing,both manual and automatic safety devices;

6.Sync Gas Recycling System:Fully burned after recycling and utilization,saving fuel and preventing pollution;

7.Direct Heating System:Enlarging heating square to lengthen the lifespan of the reactor and easy to control the temperature;

8.National Patent,Unique Heat Insulation Shell:High efficiency temperature keeping,excellent energy-saving effect.

FUEL OIL

The production rate of fuel oil is 40% in average. It's also known as tyre oil, pyrolysis oil, heating oil or furnace oil. The application is as heating fuel for industries such as power plant, cement plant, steel plant, metallurgical plant, glass plant etc.

CARBON BLACK

It produces approximately 35% of carbon black from used tyres.Carbon black is raw material for rubber&plastic industry or used as heating fuel.

STEEL WIRE

The output rate of steel wire from used tyres is 15%. It's easy to sell to scrap metal dealers.

COMBUSTIBLE GAS

Combustible gas is routed to heating system as fuel supply.It saves consumption of fuel oil.

| Item | Percentage | Usage |

| Fuel Oil | 40-45% | 1. Used as fuel in Industrial such as steel&iron factories, chemical |

| Crude Carbon Black | About 35% | 1. used for construction bricks or make into briquette; |

| Steel | 12-15% | Sold or reprocessing |

| Sync Gas | About 5% | 1. recycled and used during process as fuel. |

| NO. | ITEM |

| ||

|

1 |

Equipment Model |

XY-7-P |

XY-8-P |

XY-9-P |

|

2 |

Door type |

Full Open Door |

Full Open Door | Enclosed Auto-feeder |

|

3 |

Suitable Raw Materials |

Rubber/Plastic Products etc |

Rubber/Plastic Products etc | Rubber/Plastic Products etc |

|

4 |

Structure |

Horizontal Rotation Type | Horizontal Rotation Type |

Horizontal Rotation Type |

|

5 |

Reactor Size |

φ2200×6000mm φ2500×6600mm φ2500×7500mm |

φ2200×6000mm φ2500×6600mm φ2500×7500mm |

φ1700*8800mm φ1700*13200mm |

|

6 |

Capacity for One Batch |

5~6Mt;8~10Mt 10~12Mt |

5~6Mt;8~10Mt 10~12Mt |

20~50Mt |

|

7 |

OilYield from Tyres |

40%~45% |

40%~45% |

40%~45% |

|

8 |

Work Pressure |

Normal Pressure |

Normal Pressure |

Slightly Negative Pressure |

|

9 |

Reactor Rotation Speed |

0.4R/M |

0.4R/M |

0.5-1.2 R/M |

|

10 |

Fuels Choice |

Coal,Wood,Gas,Oil |

Coal,Wood,Gas,Oil |

Gas,Oil |

|

11 | Power |

18~22kw/h |

18~25kw/h |

18~25kw/h |

|

12 |

Cooling Method |

Cycling Water |

Cycing Water | Cycling Water |

|

13 |

Type of Drive |

External Annular Gear |

External Annular Gear | External Annular Gear |

|

14 |

Heating Method |

DirectHeating |

Direct Heating |

Hot Air Heating |

|

15 |

Type of Installation |

Without Foundation |

With Foundation/Integrated Base | With Foundation/Integrated Base |

|

16 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

17 |

Operating Mode |

Intermittent Operation |

Intermittent Operation |

Continuous Operation |

|

18 |

Total Weight(MT) |

25~40 |

25~40 |

90~100 |