Biomass briquetting machine is a kind of equipment that converts biomass raw materials (such as crop straw, wood chips, rice husks, etc.) into high-density solid fuel by physical compression. The working principle of the biomass briquetting machine: the biomass raw materials to be pressed are crushed, and then the materials are fed into the feed port through the feeding conveyor. The motor drives the reducer to drive the main shaft to rotate, and then drives the pressing roller to rotate. Under the action of the pressing roller, the material is forced to be squeezed out of the die hole to form a block or granular finished product, and falls from the discharge port.

Environmental advantages: The biomass raw materials processed by the biomass briquetting machine are renewable resources. Using biomass briquette as fuel can replace some fossil fuels, such as coal, etc., there by reducing the emission of greenhouse gases such as carbon dioxide. Moreover, biomass raw materials absorb carbon dioxide during growth and release carbon dioxide during combustion, forming a relatively carbon-balanced cycle.

High density and concentrated energy: The density of biomass briquette compressed by the briquetting machine is several times or even dozens of times higher than that of the original biomass raw materials. For example, the original stacking density of straw may be only a few dozen kilograms per cubic meter, while the density of the compressed briquette can reach 600-1200 kilograms per cubic meter. The combustion efficiency is higher and it is easier to store and transport.

Regular shape and easy to use: The shape of biomass briquette is usually a regular cuboid or cylinder, which enables them to be better stacked and burned in combustion equipment, improving the combustion stability and thermal efficiency of combustion equipment.

We have different metal crusher systems to Meet different market needs. Type1:

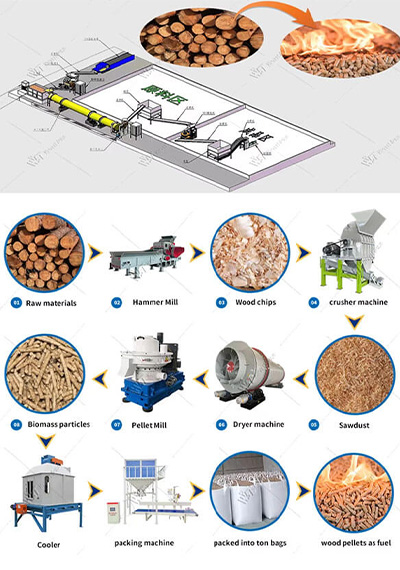

1. Wood crusher

2. Central dust removal system

3. Hot air furnace

4. Dryer

5. Pellet machine

6. Conveyor

7. Cooler

8. Packaging machine

|

Model |

Ostiole |

Spindle speed(r/min) |

Capacity(kg/h) |

Quality (kg) |

|

YK75-3 |

36 |

138 |

1000-2800 |

5000 |

|

YK75-3 |

36 |

144 |

1000-2800 |

4500 |

|

YK90-4 |

72 |

138 |

1200-2000 |

5000 |

|

YK90-4 |

72 |

144 |

1200-3000 |

5500 |

|

YK45-2 |

24 |

144 |

700-1200 |

3500 |

|

YK37-2 |

24 |

144 |

600-1100 |

3000 |