XKP Tire Crusher Machine Capacity: 200-10000kg/h ,granules 2-4mm,powder 10-120mesh. fiber,steel.

Our Hot Selling Equipment

Double shaft shredder is a powerful equipment that can crush large, difficult-to-shred or hard-to-transport materials into small pieces by shearing, squeezing and tearing, to meet the shredding requirements. It has the characteristics of low speed, high torque, strong power, good stability, adjustable discharging particle size, wear resistance, strong load-bearing capacity, easy operation, cost reduction and efficiency improvement.

XKP tyre granulator machine is used to recycle waste tires into rubber crumbs or powder through the vibrating screen as you need. The tire chips will be fed into the rubber crusher by feeding conveyor, and get grinded into target sized rubber particles. The bigger sized rubber particles will be screened out by the two vibrating screens, and returned to the rubber crusher again for further grinding until it gets to ideal sizes.

High-Quality and Durable rollers: The rollers are made of high-quality steel with a wear-resistant hard alloy overlay on the surface. They are hard and wear-resistant, and have good welding performance, which facilitates repair welding.

Excellent Temperature Control: The rollers adopt a composite process structure. There are cooling water tanks 50mm below the rollersurface, or the rollers are hollow inside, allowing the passage of saturated steam or cooling water. This effectively regulates the roller surface temperature, prevents rubber powder from carbonizing, and eliminates fire hazards.

High Degree of Automation: It adopts automatic adjustment of roller gap and auto-grease pump, making operation simple and convenient.

Convenient Adjustment: Use handwheels to adjust the roller gap, facilitating easy operation.

Easy Maintenance: The overall structure of the equipment adopts a modular design, facilitating easy repair and maintenance.

High-Quality Products: Both rollers are grooved rollers, and the inner cooling system ensures uniform roller surface temperature, which produces rubber powder with low temperature and high quality.

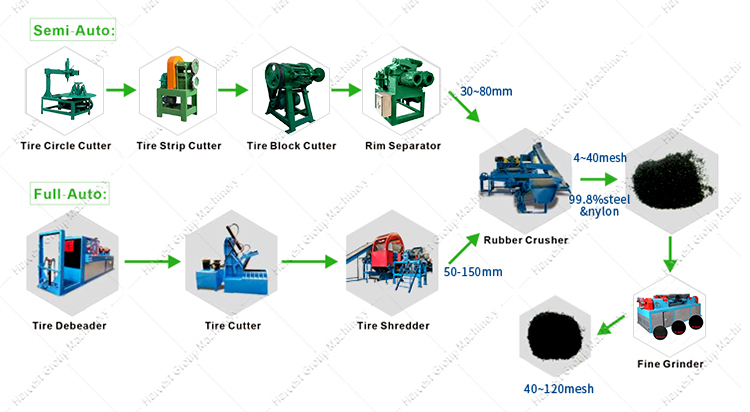

Flow chart of semi automatic xkp tire recycling line

Whole tire--tire circle cutter--tire strip cutter--tire slice cutter--crumb rubber machine--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

Fully automatic xkp tire recycling machine

Tire Cutting Machine(Tire debeader)--(Tire cutter)--Tire shredder--Rubber crusher machine--Main vibrating screen machine--Magnetic separator--Vice vibrating screen machine--Magnetic separator--Nylon fiber separator--Rubber powder

four shaft shredder

Removable blades in various sizes

Fully automatic PLC control

industrial shredding machine

Free Consulting: We provide free consulting services of different kinds of recycling equipments.

Free Consulting: We provide free consulting services of different kinds of recycling equipments.

Free Consulting: We provide free consulting services of different kinds of recycling equipments.

|

Model |

Drum diameter |

Drum length |

Front roll linear |

Roll speed ratio |

Max roller spacing |

Motor power |

Remarks |

|

XKP350 |

350mm |

500mm |

26.2m/min |

1:2.5 |

8mm |

30kw |

Antifriction bearing |

|

XKP400 |

400mm |

600mm |

34.5m/min |

1:2.5 |

8mm |

45kw |

Antifriction bearing |

|

XKP450 |

450mm |

760mm |

38m/min |

1:2.5 |

8mm |

55kw |

Antifriction bearing |

|

XKP560 |

560mm |

800mm |

38.6m/min |

1:2.5 |

8mm |

90kw |

Antifriction bearing |

|

XKP610 |

610mm |

1000mm |

42.5m/.min |

1:2.5 |

8mm |

132kw |

Antifriction bearing |

|

XKP680 |

680mm |

1000mm |

48.5m/min |

1:2.5 |

8mm |

250kw |

Antifriction bearing |

|

XKP710 |

710mm |

1100mm |

48.5m/min |

1:2.5 |

8mm |

280kw |

Antifriction bearing |

|

XKP810 |

810mm |

1100mm |

48.5m/min |

1:2.5 |

8mm |

315kw |

Antifriction bearing |

-------------

Feed waste tires into the tire shredder for primary shredding, producing tire chips under 150mm. Depending on tire size and shredder capacity, a tire debeader or cutter can be added to the process. The tire chips can be directly transferred to the crusher or stored in a temporary storage silo.