According to data from the World Business Council for Sustainable Development, over 1 billion tires reach the end of their service life globally each year. This equates to nearly 3 million waste tires requiring proper disposal daily. Without adequate management, these tires accumulate in landfills, causing environmental pollution, fire hazards, and a host of other issues.

Against this backdrop, tire shredding not only solves the waste tire disposal challenge but also generates substantial economic returns, making it an entrepreneurial choice with both environmental value and commercial potential. This article provides a detailed breakdown of the entire process for starting a tire shredding business from scratch, covering foundational knowledge, preliminary preparations, operational practices, equipment maintenance, and business expansion.

Tire shredding is a volume reduction technique primarily applied to end-of-life tires (ELTs) with tread depths below 1.6 cm (or 2/32 inch). Specialized equipment cuts these tires into smaller rubber fragments. This process effectively separates rubber, steel cords, fibers, and other components, laying the groundwork for subsequent recycling or reprocessing.

Currently, the combined shredding and grinding process is the most widely adopted method in tire recycling, handling 87.5% of the world’s end-of-life tires. This approach efficiently processes tires from all vehicle types—from standard passenger car tires to large off-road, mining, and heavy-duty vehicle tires—using appropriately scaled equipment.

Environmental Aspect: Safeguarding Ecology and Health

Reducing Landfill Pressure: 75% of a whole tire’s volume consists of voids. Direct landfill disposal not only wastes space but also occupies land long-term due to slow decomposition. Shredded tires significantly reduce volume, enabling efficient use of landfill space while preventing the release of toxic substances during burial.

Reducing Fire Risks: Stacked whole tires are highly flammable and release substantial harmful gases when burning. Shredded tires are safer to store and transport, greatly lowering fire hazards.

Advancing the Circular Economy: Materials separated through shredding—such as rubber, steel wires, and fibers—can be reused in production, reducing reliance on virgin resources and enabling resource recycling.

Improved Public Health: Accumulated waste tires attract pests, harbor mosquitoes in stagnant water, and spread diseases. Timely shredding eliminates these health hazards, creating safer communities.

Economic Benefits: Diverse Revenue Streams

Reduced Waste Disposal Costs: Compared to transporting and processing whole tires, shredded tires incur lower transportation costs and higher processing efficiency, significantly reducing waste management expenses for businesses.

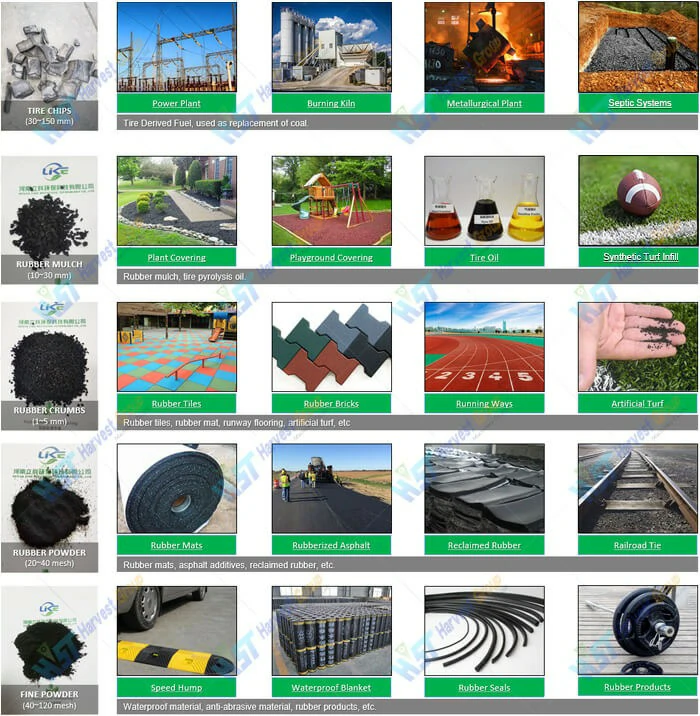

Resource Recovery Monetization: Recovered rubber can be used in rubber asphalt, sports flooring, footwear, and other products; steel wires can be recycled and re-melted, reducing energy consumption and carbon emissions in steel production. These recycled materials can be sold externally, generating stable revenue.

Expanding Energy Applications: Shredded tires can serve as Tire-Derived Fuel (TDF) for cement plants, power stations, and other facilities, replacing traditional fossil fuels. This approach is environmentally friendly and opens new profit avenues.

Market Research and Business Planning: Defining Direction and Goals

Investigate Local Demand and Resources

First, understand the volume of scrap tires generated in your region. Engage with local auto repair shops, tire retailers, and waste management companies to assess potential tire supply sources. For instance, if the area hosts numerous freight companies or large fleets, heavy-duty truck tire supply may be substantial, necessitating advance planning for suitable processing equipment.

Simultaneously, investigate local demand for recycled materials. Are nearby cement plants or power stations requiring TDF? Do rubber product factories or steel mills need recycled rubber and steel cord? This information directly impacts the business’s revenue structure.

Analyze Competitor Landscape

Examine existing local tire shredding enterprises to understand their scope of operations, equipment capabilities, pricing strategies, and service gaps. For instance, some companies may only offer tire shredding without subsequent material sales, while others may lack capacity to process large heavy-duty tires. Identifying competitors’ weaknesses enables you to carve out a differentiated positioning—such as specializing in heavy-duty tire processing or providing “shredding + material sales” one-stop services.

Develop a Detailed Business Plan

The business plan must cover multiple core modules:

Budget Planning: Clearly define expenditures for equipment procurement, facility leasing, personnel recruitment, raw material sourcing (scrap tire recycling may incur fees), and operational costs. Allocate funds reasonably to prevent cash flow disruptions.

Revenue Planning: Identify primary profit streams—such as scrap tire processing fees, sales of recycled rubber/steel cord, and TDF sales revenue—estimate projected amounts for each, and set phased profitability targets.

Compliance Planning: Tire shredding involves waste disposal. Research local environmental regulations beforehand to obtain waste disposal permits, environmental approvals, and other necessary documentation, ensuring lawful and compliant operations.

Selecting Suitable Tire Shredding Equipment: Matching Business Needs

Choose Equipment Based on Tire Type

Tires are primarily categorized as pneumatic tires and solid tires, differing significantly in structural design and material composition. Pneumatic tires typically consist of a carcass ply layer, rubber tread, and airtight layer, offering elasticity and cushioning properties. Solid tires, with their monolithic rubber structure, provide superior load-bearing capacity and wear resistance. These characteristics result in significant differences in hardness and thickness between the two tire types, necessitating the selection of compatible shredding equipment for efficient processing.

Among various shredding solutions, dual-shaft or quad-shaft cutter roll shredders are ideal for processing both tire types. These machines utilize staggered alloy steel cutter rolls that generate high-speed rotational shear and tearing forces, effortlessly breaking down the resilient rubber and cord structures. Their unique dual- or quad-shaft design not only increases throughput per unit time but also allows precise control over particle size by adjusting roller speed and blade angles. When processing pneumatic tires, the equipment effectively separates rubber, steel cords, and fiber cords. For the dense rubber layers of solid tires, it achieves uniform shredding, ensuring efficient recovery of all components. Additionally, these shredders incorporate magnetic separation units and screening systems to simultaneously remove metallic contaminants and classify particles during shredding, further enhancing the purity and quality of recovered materials.

For operations involving substantial volumes of heavy-duty tires (e.g., truck and construction machinery tires), ensure the equipment possesses sufficient cutter roll strength and motor power to handle the shredding demands of high-hardness, large-volume tires.

Parameters Based on Processing Requirements

Processing efficiency and shredding effectiveness form the core competitiveness of tire shredding operations, directly impacting operational costs and market responsiveness. During equipment selection, a comprehensive evaluation across three dimensions is recommended: processing capacity, shred size, and energy efficiency. First, select equipment capacity based on anticipated business scale. For small-to-medium enterprises processing under 5,000 tons annually, prioritize medium-sized crushers handling 200-500 tires per hour. Such equipment typically operates at 75-132kW, meeting initial demands while controlling capital investment. Second, regarding crushing effectiveness, high-quality equipment should feature multi-stage crushing capabilities to produce particles ranging from 10-50mm, meeting diverse downstream needs such as rubber granule production and steel wire separation. Additionally, models equipped with intelligent screening systems are recommended, as they enable real-time monitoring of output particle size to ensure consistent crushing quality. Furthermore, energy efficiency is a critical metric. New eco-friendly crushers reduce unit energy consumption by 15%-20% compared to traditional equipment through optimized rotor structures and motor configurations, delivering significant long-term operational cost savings.

Equipment crushing precision should be determined based on the target product. For producing fine rubber powder for high-end rubber products, select equipment with high crushing precision. For primarily producing coarse rubber chunks as TDF, crushing precision requirements can be moderately reduced, but ensure uniform chunk size meets fuel usage standards.

Adjusting Key Equipment Parameters

Blade Gap Adjustment: Adjust the gap between the cutting rollers based on tire thickness and hardness. Excessively tight gaps may cause blade collisions and wear, while overly loose gaps impair crushing efficiency and hinder effective separation of tire components. Multiple tests are required to determine the optimal gap value, balancing crushing efficiency and blade service life.

Rotational Speed Adjustment: For harder, thicker tires (e.g., truck tires, construction machinery tires), appropriately reduce the equipment’s rotational speed to enhance blade roller engagement force and ensure thorough shredding. For standard passenger car tires, moderately increase the rotational speed to improve processing efficiency. Equipment speed can be adjusted by modifying the motor speed; familiarize yourself with the speed adjustment procedure before operation.

Comprehensive Equipment and Environment Inspection

Equipment Inspection: Thoroughly examine the electrical system for normal operation, checking for potential leakage or short circuits. Verify the flexibility of transmission components (e.g., belts, gears) and inspect for looseness or damage. Ensure the crushing chamber is clean with no foreign objects remaining. Confirm blades are sharp and securely mounted. Check screens for integrity, damage, or blockages.

Peripheral environment inspection: Clear debris around the equipment to ensure ample operating space; verify the feed inlet is unobstructed to prevent material jams; ensure proper equipment grounding to prevent static electricity or leakage accidents; place safety warning signs around the equipment, demarcate the operating area, and prohibit non-operators from entering.

Conduct no-load trial operation

Before processing tires, perform a no-load trial run of the equipment. After startup, observe whether the equipment runs smoothly, noting any abnormal noise, vibration, or overheating. Check for coordinated operation of all components, such as uniform rotation of the cutting rollers and proper transmission function of the drive mechanisms.

The no-load operation should generally last no less than 30 minutes. If no abnormalities are detected during this period, the equipment is in good condition and can proceed to formal operation. If abnormalities are found, immediately shut down the equipment for inspection. After troubleshooting, repeat the no-load test until the equipment functions completely normally.

Operational Practices: Ensuring Efficient and Safe Business Operations

Real-time Monitoring of Equipment Status: Promptly Identifying Issues

Pay Attention to Abnormal Equipment Noises

During normal operation, equipment should produce steady, uniform sounds. If unusual noises are heard during operation—such as sharp metallic grinding, dull thuds, or irregular vibrations—immediately shut down the machine for inspection.

Common causes of abnormal noises include: blade misalignment and collision due to deformed grinding shafts, blade wear or damage, bearing failure, loose or broken motor belts, or foreign objects (e.g., metal fragments) entering the grinding chamber. After identifying the root cause, promptly repair or replace damaged components. Only restart the equipment after it has been fully restored to normal operation.

Ensure Smooth Material Discharge

Poor material discharge is a common operational issue, primarily caused by excessive feed rates or residue buildup in the crushing chamber. During feeding, control the material input speed according to the equipment’s processing capacity to prevent overloading the crushing chamber with too many tires at once.

Additionally, scrap tires may contain contaminants like steel wires, fibers, or stones, which can easily jam the discharge port and hinder material flow. If discharge port blockage occurs, immediately disconnect the power supply. Only after the equipment has completely stopped should you clear the obstruction. Never attempt to clear blockages with hands or tools while the equipment is running to prevent accidents.

Enhance Employee Training: Improve Operational and Safety Awareness

Standardize Feeding Procedures

Training employees in proper feeding methods is crucial for ensuring efficient and safe tire shredding operations. The following expands on operational standards, safety precautions, and handling special situations to enhance practicality and guidance.

Standardizing Feeding Procedures to Fortify Safety Defenses

In tire shredding operations, standardized feeding is fundamental to stable equipment performance and safe production. Employee training must emphasize three core principles: **“Steady Placement, Precise Sorting, and Assisted Operations”**:

Standardized Tire Placement: During feeding, ensure tires remain perpendicular to the inlet. Use both hands to evenly adjust the tire angle, ensuring the tread fully contacts the feeding platform. Avoid uneven force distribution caused by tilted tires, which can trigger abnormal equipment vibration or jamming. Implement the **“three-point positioning method”**: first secure one side of the tire, then adjust the remaining two points to ensure stable feeding.

Strict Foreign Object Screening: Establish a dedicated pre-processing zone equipped with metal detectors and manual sorting stations for dual-stage screening of recycled tires. Strictly prohibit non-tire debris (e.g., metal chunks, rocks, plastics) from entering the shredding chamber. Particular attention must be paid to metal components like steel cord and bolts embedded in scrap tires, as these can easily jam blades or damage screens. Recommend developing a **Prohibited Feed Items List** and posting it in operational areas to reinforce employee safety awareness.

Special tire handling: For construction vehicle tires exceeding 1.2 meters in diameter or 200 kilograms in weight, use a forklift with specialized clamps for lifting operations. Maintain a safe distance between the forklift and feed inlet (recommended minimum 1.5 meters) during operation, with a designated person directing precise tire placement. Regularly inspect the forklift’s braking system and clamp fastenings to ensure flawless auxiliary feeding procedures.

Define Emergency Response Procedures

Inform employees of emergency protocols for common malfunctions, such as shutting down equipment upon abnormal noises or vibrations, safely clearing discharge port blockages, and disconnecting power during electrical faults. Establish reporting procedures for critical incidents. For unresolvable issues, promptly contact the equipment manufacturer or professional maintenance personnel to prevent repair delays.

Emphasize Safety Protective Measures

Require employees to wear complete safety gear during operation, including slip-resistant gloves, safety goggles, earplugs (to reduce equipment noise impact), hard hats, and slip-resistant work shoes. This prevents injuries from rubber fragments, wire cuts, noise exposure, or dust inhalation.

Additionally, employees are strictly prohibited from approaching hazardous areas such as the crushing chamber or discharge port while the equipment is running. Hands or any other body parts must not be inserted into the equipment to ensure personal safety.

Ensure Quality Control of Finished Products: Enhancing Product Value

Efficiently Separate Tire Components

The mixture produced after tire shredding contains rubber, steel wires, fibers, and other components. Specialized separation equipment (e.g., magnetic separators for steel wires, vibrating screens for fibers) must be used to separate these materials. Ensure thorough separation during this process. For instance, excessive residual steel wires in rubber will reduce its subsequent value, while significant rubber contamination in steel wires will decrease the efficiency and profitability of steel recycling.

Regularly inspect the operational status of separation equipment and adjust parameters to ensure separation meets expected standards, laying a solid foundation for the sale of different components.

Controlling Finished Product Particle Uniformity

Different customers have varying requirements for the particle size of shredded tire products. For example, TDF used in cement plants typically requires particles around 2 inches, while rubber product factories may need fine rubber powder under 0.5 inches.

During production, adjust crushing parameters (e.g., blade clearance, rotational speed) according to customer specifications. Use screens to ensure uniform particle size compliance with application standards. Conduct regular sampling inspections of finished particles. If non-conformities are detected, promptly adjust equipment parameters to prevent sales disruptions.

Equipment Maintenance: Extend Lifespan, Ensure Stable Profitability

Daily Maintenance: 10 Minutes Daily to Prevent Failures

Clear Residual Materials from Equipment

After daily shutdown, promptly remove residual rubber fragments, steel wires, fibers, and other materials from the grinding chamber. Prevent accumulation that could disrupt subsequent operations or cause component damage from prolonged compression. Use specialized tools during cleaning to avoid damaging the chamber walls or blades.

Check Blade Screw Tightness

Blade screws secure the grinding blades to the cutter rollers. During operation, blades endure significant impact forces that can loosen screws. Daily inspection is required. If any screws are loose, tighten them immediately with a wrench to prevent blade detachment during operation, which could cause equipment failure or safety incidents.

Ensure Motor Ventilation and Heat Dissipation

The motor is the core power component of the equipment. It generates substantial heat during operation, and inadequate heat dissipation can lead to motor overheating and damage. Daily inspection is required to ensure the motor’s ventilation openings are unobstructed. Clean any dust or debris from these openings to guarantee proper heat dissipation. Additionally, avoid stacking objects around the motor to maintain an unobstructed ventilation environment.

Check Blade Sharpness

Blade sharpness directly impacts crushing efficiency and product quality. Before daily operation, inspect blade edges. If dullness, nicks, or severe wear is detected, promptly sharpen or repair the blades. If wear is irreparable, replace the blades to prevent reduced crushing efficiency or non-compliant particle sizes.

Cleaning the Equipment Surroundings

Daily clean the floor around the equipment, removing scattered rubber fragments, steel wires, dust, and other debris to maintain a tidy operating area. This not only creates a safe and comfortable working environment for employees but also prevents foreign objects from entering the equipment, reducing the likelihood of malfunctions.

Regular Maintenance: Weekly/Monthly Key Inspections to Eliminate Hazards

Regularly Replace Worn Blades

Develop a blade replacement schedule based on equipment usage frequency and tire processing volume. Generally, blades should be replaced every 1-2 months for equipment operating at full capacity daily (adjust timing based on blade material and usage conditions). When replacing blades, strictly follow the manufacturer’s instructions to ensure proper and secure installation. Conduct an idle test after replacement to confirm normal equipment operation.

Lubricate Equipment Bearings Weekly

Bearings are critical components of the transmission system and are prone to wear from friction during prolonged operation. Weekly lubrication of all bearings is required. Use appropriate lubricating oil and apply it in the specified quantity to ensure thorough lubrication, reduce friction loss, and extend bearing lifespan. After lubrication, inspect bearing operation to confirm no abnormalities exist.

Inspect and tighten connection components

Equipment vibration during operation can loosen various connection points (e.g., base bolts, transmission linkages, pipe joints). Conduct monthly comprehensive inspections of these connections. Tighten any loose components promptly to prevent equipment displacement, increased vibration, or potential safety incidents.

Adjust conveyor belt tension

The conveyor belt transports crushed products from the discharge port to designated locations. Over time, prolonged use may cause the belt to stretch and loosen, reducing transmission efficiency or causing slippage. Monthly inspections should assess belt tension. If excessive slack is detected, adjust the tensioning device to restore proper tension, ensuring reliable material conveyance.

Check hydraulic system status

If the equipment incorporates a hydraulic system (e.g., for adjusting blade clearance), inspect the hydraulic system monthly. Verify the hydraulic oil level is normal, assess oil cleanliness, and check for leaks (e.g., at pipe joints or cylinder seals). If the oil level is low, replenish hydraulic oil promptly. If the oil has degraded, replace it with fresh oil. Address leaks by replacing seals or repairing pipes to maintain proper hydraulic system function.

Monitor Motor Operating Current

Motor operating current is a critical indicator of motor health. Excessive current may indicate overload, which can lead to motor burnout if sustained. Monthly use of an ammeter is required to verify the main motor’s current remains within the equipment’s specified normal range. If abnormal current is detected, promptly investigate causes such as excessive feed volume or component jamming, and implement corrective actions.

New Equipment Maintenance: Implementing Routine Care from Day One

Contrary to common misconceptions, new equipment requires diligent maintenance. During the initial break-in period, all components undergo adjustment and wear. Regular maintenance is essential to ensure smooth operation and establish sound maintenance practices.

From the first day of operation, strictly adhere to daily and periodic maintenance protocols. Document equipment status, maintenance activities, and any malfunctions. Through consistent maintenance, potential issues (such as factory-unnoticed component loosening or parameter deviations) can be detected early. This process also familiarizes operators with the equipment’s performance and maintenance essentials, laying the groundwork for long-term stable operation.

Adhering to new equipment maintenance effectively extends the equipment’s lifespan, reduces future failure rates, and safeguards the continuity of business profitability.