HVST offers customized industrial shredders for the waste disposal and recycling industry that work individually or in tandem to reduce material to the required size quickly and efficiently.

The single shaft shredder utilizes cutters mounted on the rotor to shred materials through rotation, offering material adaptability, high throughput, small finished size and consistent performance. With screens designed specifically for single-shaft shredders, it is easy to meet the required final size of material in a single pass with just one single machine

The single shaft shredder utilizes cutters mounted on the rotor to shred materials through rotation, offering material adaptability, high throughput, small finished size and consistent performance. With screens designed specifically for single-shaft shredders, it is easy to meet the required final size of material in a single pass with just one single machine

HVST-series plastic shredder is designed to meet the waste recycling requirements of various industries and is suitable for plastic, paper, wood, fiber, rubber, domestic garbage recycling, etc., there are many types of recyclable materials.

HVST-series plastic shredder is designed to meet the waste recycling requirements of various industries and is suitable for plastic, paper, wood, fiber, rubber, domestic garbage recycling, etc., there are many types of recyclable materials.

scrap shredder for sale

large industrial shredder

single shaft shredder machine

auto shredder machine"

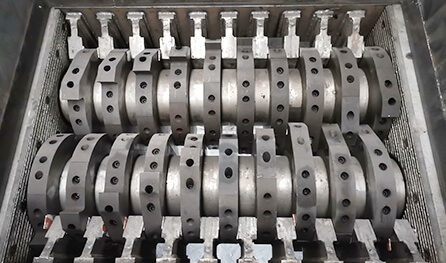

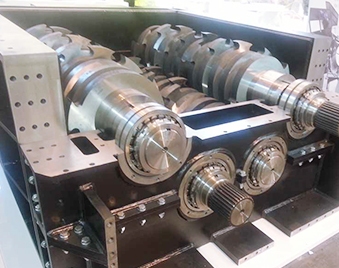

he Double-Shaft Shredder is a widely used industrial shredder with low speed, high torque and high throughput, designed to efficiently process a wide range of materials. It can be equipped with different components or work with other stages of shredders depending on the material and final size, reducing the material to the required size.

he Double-Shaft Shredder is a widely used industrial shredder with low speed, high torque and high throughput, designed to efficiently process a wide range of materials. It can be equipped with different components or work with other stages of shredders depending on the material and final size, reducing the material to the required size.

HVST-series plastic shredder is designed to meet the waste recycling requirements of various industries and is suitable for plastic, paper, wood, fiber, rubber, domestic garbage recycling, etc., there are many types of recyclable materials.

HVST-series plastic shredder is designed to meet the waste recycling requirements of various industries and is suitable for plastic, paper, wood, fiber, rubber, domestic garbage recycling, etc., there are many types of recyclable materials.

metal shredder for recycling

steel scrap shredding machine

metal shredder manufacturer

double shaft shredder machine

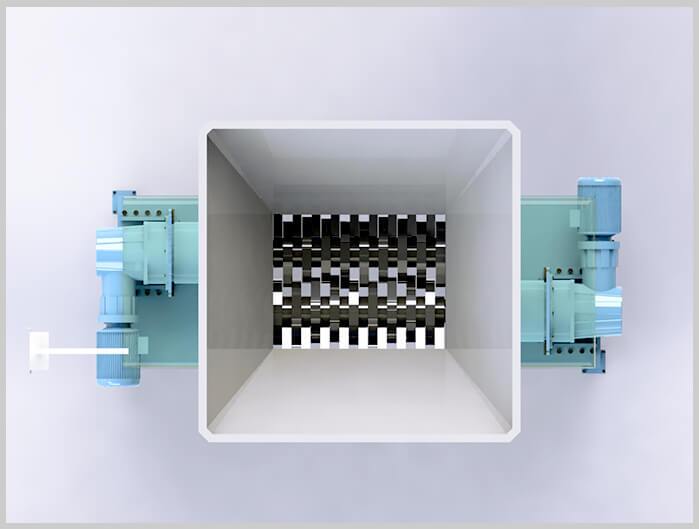

Engineered for the most challenging materials, our four-shaft shredder delivers high-throughput processing and uniform output in a single pass. Its four shear shafts with matched cutters tear, shear, and shred bulky waste efficiently.

Engineered for the most challenging materials, our four-shaft shredder delivers high-throughput processing and uniform output in a single pass. Its four shear shafts with matched cutters tear, shear, and shred bulky waste efficiently.

A sizing screen controls output, ensuring only particles smaller than the screen holes are discharged. Powered by a high-torque motor and reducer, it easily processes metal, industrial waste, and bulky scrap.

A sizing screen controls output, ensuring only particles smaller than the screen holes are discharged. Powered by a high-torque motor and reducer, it easily processes metal, industrial waste, and bulky scrap.

Ideal for large-scale recycling and waste reduction applications.

Ideal for large-scale recycling and waste reduction applications.

Choose the HVST Series for high-capacity shredding and a cleaner, more efficient recycling process.

four shaft shredder

heavy duty metal shredder

metal recycling equipment

industrial shredding machine

HVST has the right machines for a volume reduction and controlled size shredding processes.

Industrial Shredders are used in a wide range of applications in recycling and waste disposal industry in reducing size or volume in large batches by shearing, tearing or crushing. It is divided into single-shaft shredders, double-shaft shredders and four-shaft shredders. Double-shaft shredder meets most material disposal requirements thanks to its high shredding ratios, consistent work efficiency and low failure rates.

Single-Shaft Shredder

Double-Shaft Shredder

Four-Shaft Shredder

As one of the most important industrial shredder machines, four shaft shredders find applications in various industries and waste management processes. They are commonly used for shredding bulky and tough waste materials, such as plastic bottles, containers, pallets, wood scraps, cardboard, metal drums, tires, and more. Four shaft shredders are widely utilized in recycling facilities, waste-to-energy plants, municipal solid waste management centers, and industries that generate significant volumes of waste.

Industrial Shredders are used in a wide range of applications in recycling and waste disposal industry in reducing size or volume in large batches by shearing, tearing or crushing. It is divided into single-shaft shredders, double-shaft shredders and four-shaft shredders. Double-shaft shredder meets most material disposal requirements thanks to its high shredding ratios, consistent work efficiency and low failure rates.

HVST's industrial shredders have an extremely wide range of applications and are capable of processing municipal waste, bulky waste, industrial hazardous waste, waste tyres, non-ferrous metals, electronic waste, plastics, cardboard and all other solid wastes. Combined with advanced intelligent control systems,HVST helps customers to increase project automation and availability, reduce operating costs and system risks to achieve long-term development plans