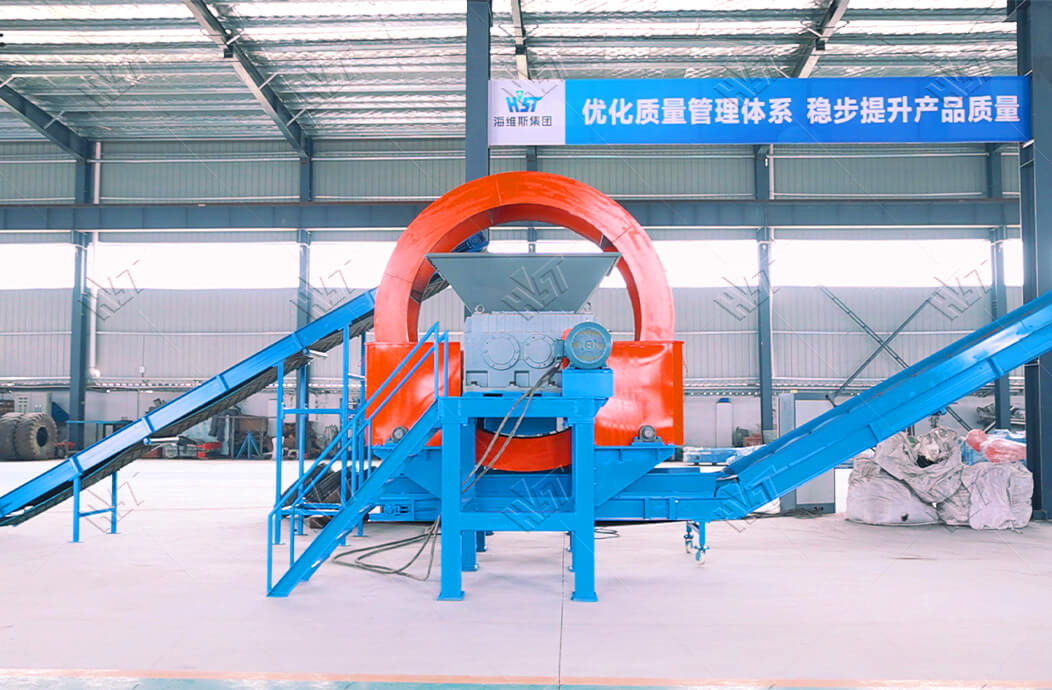

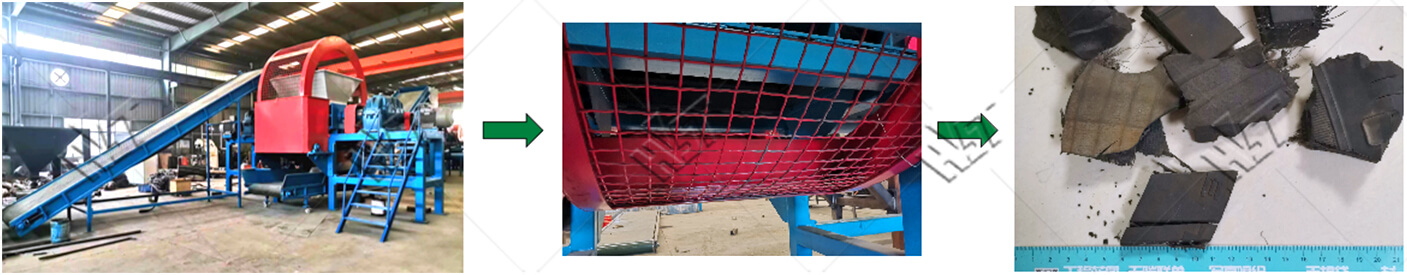

HVST's two - shaft tire shredding machine are specially designed for shredding whole tyres into rough shreds for disposal or further processing into Tyre Derived Aggregate (TDA), Tyre Derived Fuel (TDF), or as feedstock for crumb rubber applications.

The thickness of all the rubber shredder machine blades ranges from 50 mm to 150 mm, depending on the type of tyres, output, and final product. Rubber Shredding Machine can process OTR tyres, big truck tyres, and passenger car tyres at a rate of 1 ton to 35 tons per hour.

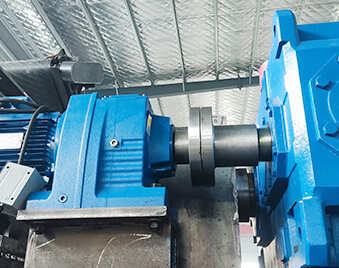

High efficiency: two axes work simultaneously, with strong processing capacity and fast shredding speed.

Uniform shredding: Crumb Rubber Machine'blades are staggered to ensure uniform tearing of materials and avoid single-point overload.

Reduced energy consumption: the cooperation of two axes disperses the force, reduces the wear of individual components, and reduces energy consumption.

Durable knives: high-quality alloy knives are used, which are wear-resistant and corrosion-resistant, and can be welded and repaired after damage.

Anti-winding design: effectively prevents materials from winding around the blades and reduces the frequency of downtime for repairs.

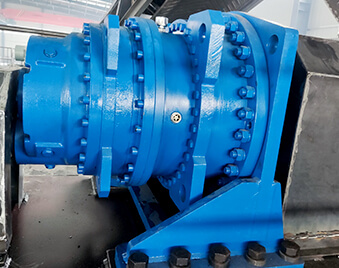

Good sealing: the quadruple sealing system ensures safe and stable sealing of the machine in complex environments.

Automatic reversal protection: when the motor is overloaded or the material is blocked, the knife shaft automatically reverses to protect the machine.

Rubber Tire Shredder Machine Processes whole tyres into rough shreds for disposal or further processing to Tyre Derived Aggregate (TDA), Tyre Derived Fuel (TDF), or Feed Stock for Crumb Rubber Applications. Two-shaft shredders are slow or high speed primary shredders which are typically the first industrial machine waste materials see. These are powerful units that cut and shred raw materials down to manageable sizes. Typical two-shaft Tire Recycling Shredder output 2”-6” inch waste shreds for use or further processing.

Tire Rubber Recycling Shredder Machine can process Car tires,OTR tyres, big truck tyres, Waste Rubber Products,passenger car tyres at a rate of 1t-30t in one hour.

Type1:Circular screener is suitable for small output size (50~60mm), and normal capacity (1~5 t/h)

Type2: Disc screener is suitable for bigger output size (75~150 mm), and high capacity (5~15 t/h)

We also have Rubber Rasper, Rubber Granulator, Rubber Miller and OTR Tyre Cutting Machine for tyre recycing. If you need these machines, Pease feel free to contact us!

Please leave a message for your requirements, the machine can be customized for you.

|

Model |

Input size |

Output size |

Cappacity |

Motor |

Blades quantity |

Dimensions |

Weight |

|

TS-800 |

800mm |

50*50mm |

1-2T/h |

2*22kw |

16pcs |

4*2.6*3.2m |

8T |

|

TS-1200 |

1200mm |

60*60mm |

3-5T/h |

2*45/55kw |

20pcs |

4.8*2.8*3.5m |

14T |

|

TS-1600 |

1600mm |

50-150mm |

6-8T/h |

2*75kw |

16-30pcs |

5*2*3.4m |

18T |

|

TS-1800 |

1800mm |

50-150mm |

7-10T/h |

2*90/110kw |

20-24pcs |

5.6*2*3.4m |

23T |

|

TS-2000 |

2000mm |

75-200mm |

10-15T/h |

2*110kw |

20-30pcs |

6*2.4*4m |

36T |

|

TS-2400 |

2400mm |

100-200mm |

20-30T/h |

2*160kw |

16-24pcs |

7.4*3.2*5.2m |

56T |